CMT: The trial of the “Stethoscope for Cylinders” system

In the maritime sector, one of the most insidious and costly issues concerns cylinder liner scuffing in two-stroke diesel engines, typically used on cargo vessels, tankers, and large container ships.

This phenomenon, characterized by sudden and severe wear, can cause serious engine damage, resulting in prolonged vessel downtime and high repair costs. To address this challenge, CM Technologies (CMT), a German company recognized as a leader in advanced condition monitoring solutions, has launched a collaborative trial to validate an innovative early detection system called “Stethoscope for Cylinders.”

Germany s CMT has developed a system that can alert operators to early onset cylinder damage, but see seeks trial partners for critical data gathering

The trial aims to involve shipowners and fleet managers in the real-time monitoring of two-stroke engines, with the goal of promptly identifying the earliest signs of scuffing and preventing catastrophic failures. This article examines in detail the significance of the challenge, the technology developed by CMT, and the strategic value of industrial collaboration for the future of marine maintenance.

The Challenge of Scuffing in Two-Stroke Marine Engines

Scuffing is a form of wear that can occur suddenly within cylinder liners, causing extensive and often irreversible damage if not addressed promptly. Although it is a well-known issue in the maritime industry, its exact causes remain difficult to determine. Among the main contributing factors are lubrication failures, abrupt variations in engine load, recent overhauls, and other complex operational conditions.

This uncertainty makes it challenging for shipowners and engine manufacturers (OEMs) to accurately predict when and how the phenomenon will occur, limiting the effectiveness of preventive maintenance strategies and frequently leading to significant costs for emergency repairs and vessel downtime.

The “Stethoscope for Cylinders” System: A New Frontier in Acoustic Monitoring

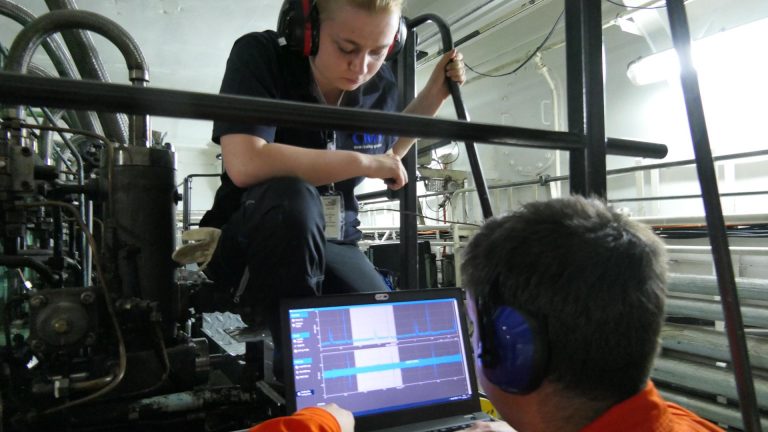

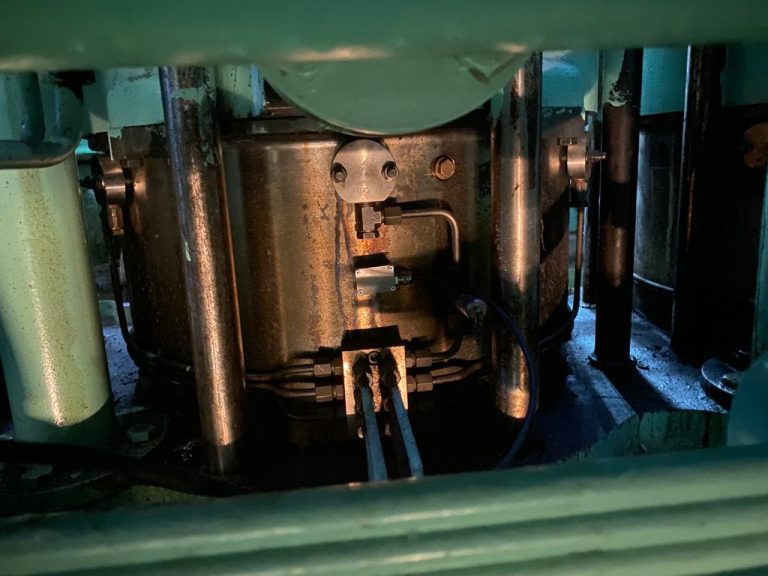

To overcome these challenges, CM Technologies has developed a monitoring system based on high-frequency acoustic emission (AE) technology, capable of detecting the earliest signs of friction and wear from outside the cylinder. Defined as a true “stethoscope for cylinder liners,” the system captures real-time acoustic data generated by metal surfaces, providing an early warning before damage becomes apparent.

This innovation represents a major step forward compared to traditional methods, which rely on visual inspections or oil analysis conducted weeks apart—often too late considering how quickly scuffing can develop. The CMT system is designed to be non-invasive: sensors are mounted externally on the cylinder liners using magnetic supports, requiring no disassembly or interruption of operations. Moreover, it does not require any internal engine modifications or dry-docking, enabling continuous and unobtrusive monitoring.

CMT

The Trial: Involvement of Maritime Operators and Objectives

The current phase involves the participation of shipowners and fleet managers willing to install the system on two-stroke engines already operating aboard their vessels. The ideal ships for the trial are those calling at ports in Northern Europe—including Germany, the Netherlands, Belgium, and France—allowing CMT engineers easy access for installation and data collection.

The planned monitoring period ranges from one to three months, during which the system continuously collects operational data from the engines. Building a large acoustic database from multiple engines will enable the development of a library of noise patterns associated with wear and scuffing phenomena, thereby enhancing the system’s predictive and early warning capabilities.

According to CM Technologies’ management, this collaboration represents a valuable opportunity for maritime operators to gain early insight into the risks their engines may face, providing tangible benefits in terms of reduced maintenance costs and minimized vessel downtime.

Benefits and Impact on the Maritime Sector

The system developed by CMT has the potential to revolutionize two-stroke engine maintenance, shifting from a model based on periodic inspections and reactive repairs to one founded on continuous monitoring and predictive maintenance. This transformation not only improves vessel safety and reliability but also leads to significant optimization of operational costs.

The ability to detect early signs of scuffing can prevent catastrophic engine failures, reducing the need for costly emergency interventions and long periods of inactivity. Protecting a critical asset such as the two-stroke main engine—the true heart of a vessel—safeguards a major investment, both economically and in terms of crew safety and overall ship performance.

Furthermore, the collaboration between CMT and maritime operators underscores the importance of an integrated and participatory approach in addressing complex technological challenges. Only through extensive data collection and knowledge sharing will it be possible to refine monitoring technologies and adapt them effectively to the diverse operational conditions of the maritime industry.

CMT

The trial of the “Stethoscope for Cylinders” system represents a major step forward in addressing scuffing in two-stroke diesel engines—one of the most challenging and costly issues in the maritime industry. Thanks to the innovative acoustic emission technology developed by CM Technologies, it will now be possible to detect early signs of wear, enhancing preventive capabilities and reducing the economic and operational impact of potential failures.

The participation of shipowners and fleet managers in this experimental phase is crucial for collecting essential data and refining the system, which is expected to become an indispensable tool for predictive maintenance in the marine sector. The collaboration between technology developers and maritime operators highlights how innovation, combined with a shared vision, can pave the way for a safer, more sustainable, and efficient future for global shipping.

With this initiative, CM Technologies reaffirms its position as a leader in the development of advanced condition monitoring solutions and invites interested maritime operators to join this pioneering project, which may set new standards for condition-based maintenance and operational safety in the industry.

Stay tuned for more news, updates, and reviews from the world of cruising on Cruising Journal.