Emissions Reduction: The Life-Cycle Assessment

Reducing emissions and combating pollution are the most discussed topics in the shipping industry due to the ever-increasing need to protect the environment.

Previous editions have showcased some of the possible solutions to do this, including alternative fuels (methanol, liquid natural gas, hydrogen) and nuclear solutions. However, the search for the alternative solution shall consider many aspects and not only the emissions from its use on board.

It is, in fact, necessary to evaluate the entire production cycle to take into account the emissions produced both during use, but also during production, transportation, and possibly even disposal. This is done using what is known as Life-Cycle Assessment (LCA), which is a structured and internationally standardized method for quantifying the potential impacts on the environment and human health associated with a good or service from its respective resource consumption and emissions.

Such a tool is especially necessary in an age when it is common to advertise “green” products and solutions that are, however, often only so in appearance. A classic example is related to which is the best kitchenware to use. Through an LCA study conducted in 2015, analysing the entire life cycle, it was found that using porcelain dishes has the least environmental impact (considering a life cycle of 1000 washes).

LCA

Comparing porcelain with disposable products, it was found that the second-best solution is related to the use of polypropylene and polystyrene products (the common plastic plates), followed by PLA products and finally, with significantly higher values in terms of pollution, products made from cellulose. This seemingly surprising conclusion clearly shows how important this kind of study is to avoid “passing off” a solution as “green” when, as in this case, it turns out to be the worst from an environmental point of view.

The LCA study can, therefore, be conducted for any product and consequently also for fuels. Any system of analysis obviously must consider a whole range of conditions and must be universally applicable to avoid false results.

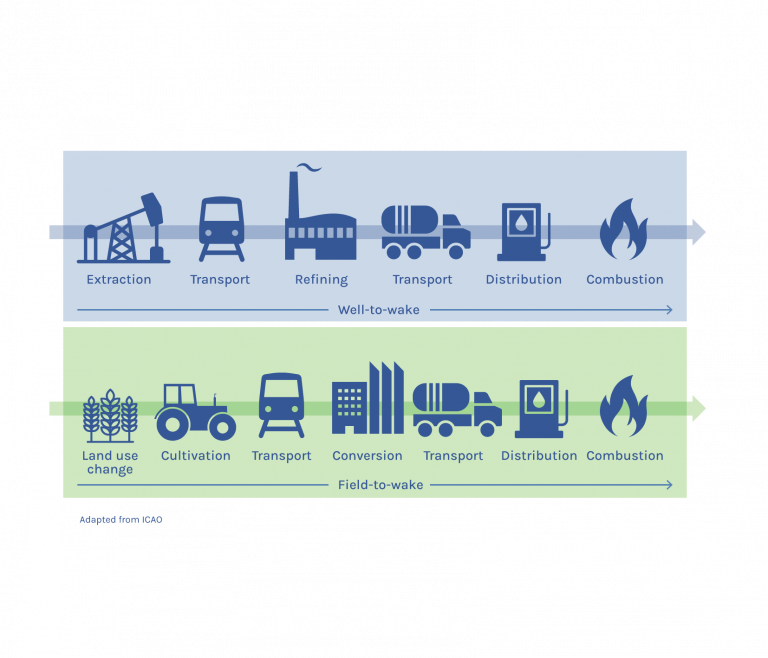

Therefore, in the maritime field it has been decided that the best system is to compare the CO2 emissions of current fuels with ‘future’ fuels. The candidate measure in IMO’s Initial GHG Strategy refers to the development of life-cycle CO2 intensity guidelines for all types of fuels, referring to the assessment of GHG emissions from fuel production to use on board the ship. This is necessary because future low-carbon and zero-carbon fuels have different production pathways (e.g., different generations of biofuels, hydrogen fuels, etc.) that result in significant differences in their overall environmental footprint.

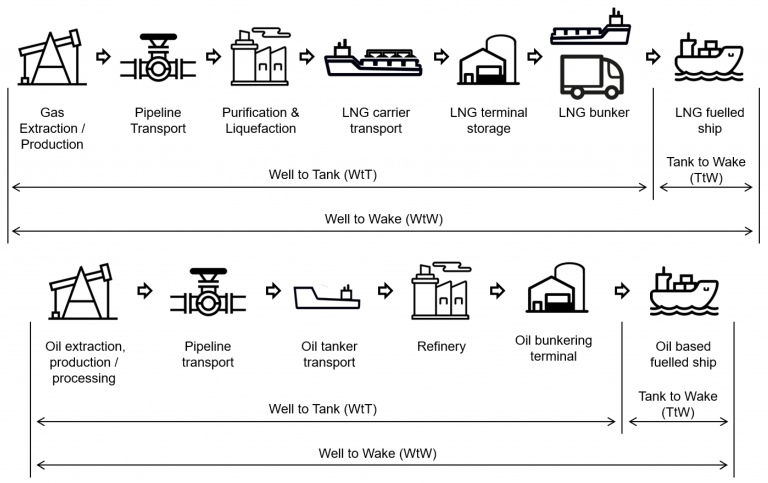

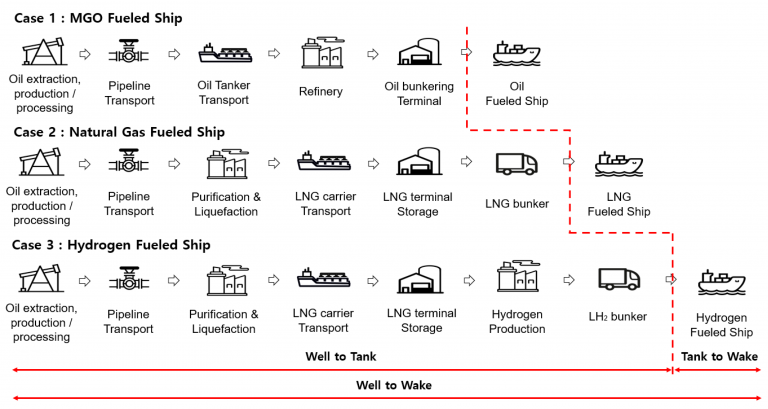

To properly address this need, the analyses are conducted by assessing CO2equivalent carbon dioxide emissions in the entire Well-to-Wake process (from production to use) as the sum of “upstream” emissions (well-to-tank, from production to tanks), then extraction, processing, transport, and “downstream” emissions (tank-to-wake, from tanks to the usage), then bunkering, storaging on board and consumption. In addition to carbon dioxide (CO2) itself, CO2 equivalent also includes greenhouse gases (GHGs) such as methane and nitrous oxide.

Costa Smeralda

This is because focusing solely on CO2 and ignoring other pollutants would risk significantly underestimating the climate pollution caused by shipping, which would hinder the achievement of the Paris Agreement’s goal of limiting global warming to 1.5 degrees Celsius above pre-industrial levels.

The assessment process is based on Document 5213/22 dated January 11th 2022 issued by the Council of the European Union, which allows calculation of GHG emission factors for both fuels and other energy sources over the entire supply chain as the sum of 2 different contributions: GHG WtT (Well-to-Tank) and GHG TtW (Tank-to-Wake). These factors are obtained by calculating GHG CO2e emissions, evaluated against values of global warming potential over a 100-year horizon (GWP100), which identifies the heat absorbed by any GHG in the atmosphere as a multiple of the heat that would be absorbed by the same mass of carbon dioxide.

LCA

Considering a cruise ship and its energy demands (mainly distinguishable into 3 macro areas: propulsion, air conditioning and miscellaneous services), the following possible alternative solutions were analysed:

– Traditional fuels: heavy fuel oil (HFO) and marine gas oil (both MGO and MDO);

– Methanol, in “green’ versions-the cleanest (obtained through plant fermentation processes) and “brown”-the most polluting;

– Ammonia;

– Hydrogen (through the use of Fuel Cells;

– Liquefied Natural Gas (LNG);

– Lithium-ion batteries.

After performing a Well to Wake LCA study, the following conclusions were reached:

Based on CO2e values emitted by the various fuels, the best solution is apparently to use methanol (green) ensuring the best environmental performance at a loss of range of about 50% (for the same amount of available space on board in comparison with the use of traditional fuels (HFO/MGO/MDO);

Such a solution, however, is currently feasible only for newly built ships or through heavy investment due to the need for particularly aggressive retro-fits that require at least 2-3 months of work, as well as having to re-engineer numerous on-board systems (with significant costs, both design and construction). A conversion to methanol also involves considerable changes in the weight distribution on board, and this for some ships may be such a condition that it would not be possible to proceed.

LCA

In any case, methanol turns out to be the best solution only if it is used in its “green” variant because using non-green methanol results in more emissions than any other fuel. Currently, however, it is not possible to use green methanol because of its still low production, cost and extremely limited supply chain.

The alternative solution, albeit more polluting than methanol, but considerably less than traditional fuels is to use liquid natural gas (LNG). This solution, however, requires the use of specific tanks on board, the placement of which is strongly constrained by safety regulations and is therefore not applicable to already built ships but only to new constructions since, in a nutshell, one must build the ship around the tanks. In addition, and it is necessary to consider some problems arising from the use of LNG, for which, however, the market immediately provided solutions, many of which are already in use.

The use of batteries, from an LCA perspective, and the least effective solution given the high pollution factor due to battery production and disposal combined with the factor of low power density. Current batteries (lithium) involve taking large weights on board while ensuring relatively little power (about 6 tons for 1MW). They remain, however, a viable solution for “smart” uses such as, for example, during port hours on board ferries. On today’s cruise ships, which at low loads anyway require no less than 2 to 3 MW, the amount (and thus the weight) would be too much to allow their use.

carnival-celebration-seatrials-abgeschlossen

Finally, based on the limits shown by today’s technologies, a further possibility to contain emissions is to use non-fossil fuels, such as HVO, FAME and biofuels, which can concretely decrease the amount of emissions, possibly even being able to be blended with traditional fuels.

As can be seen hydrogen, as well as ammonia, have not been considered as to date, their production and currently polluting. In the case of hydrogen there are currently no Fuel Cells yet such as to meet the power needs required by ships. Numerous companies, however, are working on the development of this technology, which is widely used, for example, by navy submarines (the U212-A use, in fact, hydrogen-powered fuel cells for underwater navigation). The current study concerns the on-board storage aspect, which is complicated by the physical properties of the latter. A new, truthful LCA assessment can only be done when all the data are available to produce not only the fuel itself but also everything the supply chain (transport, storage) needs.

Mardi Gras

In conclusion, research in shipping has never been more determined to find one or more solutions for reducing emissions as well as consumption, as they not only have a strong impact on the environment but also on the shipowners themselves. It is not easy to identify a single, universally valid solution, but as it were, the path has been laid out, and the years to come will tell us what direction will be taken. As of today, however, we know very accurately what each solution entails and based on this knowledge it is necessary to develop even more innovative solutions.

Don’t miss further news, updates and reviews on the world of cruises on Cruising Journal.